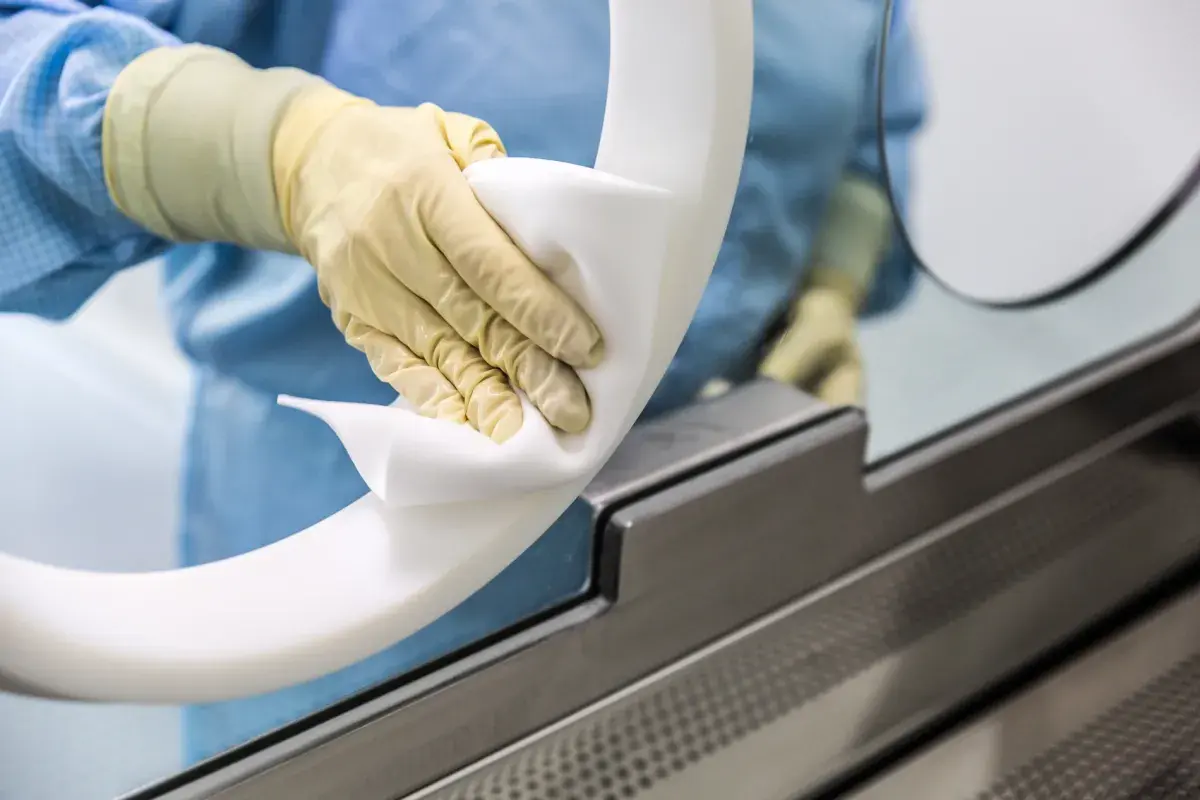

Passion for Cleaning

We offer cleaning and disinfection in all cleanliness classes of sterile and dust-free production, so that your cleanroom processes can run safely at all times (cleanliness classes A - D according to EU GMP guidelines, classes 1 - 9 according to DIN EN ISO 14644).

For the highest quality standards in your cleanroom

We offer cleaning and disinfection in all cleanroom classes of sterile and dust-free production so that your cleanroom processes can run safely at all times (cleanroom classes A - D according to EU GMP guidelines, classes 1 - 9 according to DIN EN ISO 14644).

Even minimal contamination by particles or microorganisms is reliably eliminated. To ensure these highest quality standards, we work exclusively with intensively trained specialists who we regularly train and educate in our own cleanroom academy.

Cleaning in the pharmaceutical, life science & electronics sector

Adjoining areas & laboratories

- Regular maintenance cleaning

- Laboratory cleaning S1 - S3

- Hygiene and disinfection services

- Plant and machine cleaning

- Industrial cleaning

- Glass and facade cleaning

- Rough and fine construction cleaning

- Special and specific cleaning

Certified

CWS has the following certifications:

DIN EN ISO 14644-1, 45001 & 14001.

FAQs

How do you train your employees?

- All our employees are trained in a 2-week basic training course to become “Clean Operators”. This teaches them the basics of how to behave in cleanrooms.

- They are trained to behave correctly in your cleanroom and to carry out the cleaning and disinfection processes in a reliable and qualified manner.

- According to our training plan, all employees must complete three continuous training courses per year (quality training courses). The training programme is rounded off by contingency-specific training courses.

- Finally, we have established a multi-stage individual internal qualification system.

How does CWS cover itself in the event of absences due to illness?

We employ additional staff in order to be able to deploy trained personnel whenever necessary due to absences.

Depending on the size of the location, there is always a personnel buffer and regional and national “sweepers”.

What is your reaction time in the event of an accident?

Depending on the extent of the damage, we can be on site quickly. For small jobs, we will be there within 2 hours, for larger jobs we should have enough staff on site within 24 hours.

What to do in case of contamination in the cleanroom?

In general, the cause of contamination should be clarified in order to initiate the correct cleaning or disinfection measures. Our team are trained to professionally removes any type of contamination!

Benefits of working with us

Reliable quality assured service

When it comes to cleaning and disinfecting cleanrooms, your standard operating procedure (SOP) is our benchmark. This ensures that your processes are secure at all times.

Highest standards of safety

We take over the cleaning and disinfection for you, so that your employees can concentrate on their core activities. The Proficon service includes documenting the cleaning processes.

Your specific requirements

Our employees are trained several times a year and perform the cleaning work according to your specific SOPs. We are also happy to support you in the preparation of your internal documentation.

Fast and flexible task force

A team of floaters is always on standby (365/7/24), so that we can be on the spot at short notice even in the case of unforeseen events such as an accident.

Cleanroom cleaning training

In addition to cleaning by our experts, we also offer training for your cleanroom staff.

The trainings of our cleanroom academy take place by means of day trainings in our locations, in your premises by in-house trainings & coachings or online with trainer.

More solutions for your cleanroom

On-Site Service

- Ensuring availability

- Quality management

- Logistics Processes

- Process analysis & standardisation

Cleanroom textiles

- Individual & sustainable rental solutions

- Professional preparation

- Inventory monitoring

- Competent advice

Cleanroom training

- Inhouse trainings

- Coachings

- Day trainings

- Online learning platform & seminars

Personal hygiene

- CWS Smartwash

- Hand Sanitizers

- Cloth towel rolls